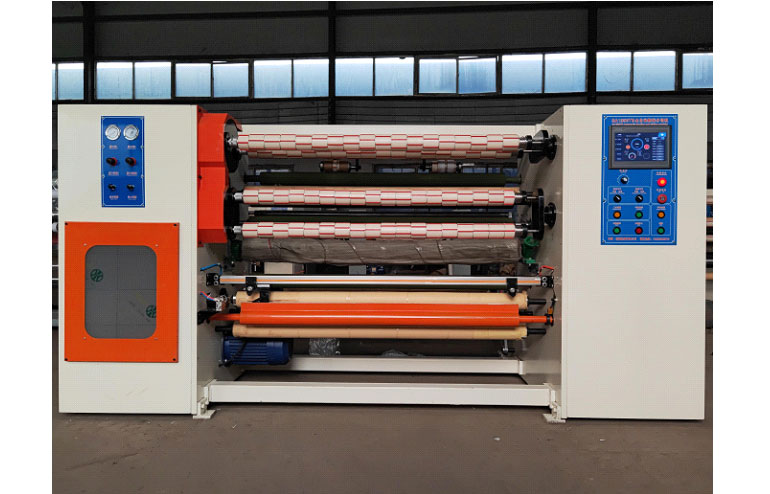

Function advantages: 1. Fully automatic labeling, reducing labor intensity for workers. After setting the number of meters, it can automatically label with adhesive tape and arrows, saving process. 2. Intelligent high-end 10 inch touch screen control, meters/yards, automatic conversion of deceleration distance, simple and convenient. 3. 0-260 meters/minute high-speed slitting and slitting, automatic roll changing. 4. Classic new technology noise reduction silencer, reducing 60-70% noise. 5. Efficient non-stop up and down winding shaft, producing neat and beautiful finished products, improving production efficiency by 50%. 6. Swinging coiling, left and right rollers collect large roll waste edges, and can collect multiple semi-finished large roll waste materials at once. 7. Automatic feeding, which can automatically load the mother roll semi-finished products, is very practical and reduces labor intensity for workers. 8. The pneumatic expansion shaft master material is fixed, convenient and durable. 9 Magnetic powder brake buffer discharge (automatic tension control)

1. PLC touch screen control (Kunlun connected state), 10 inch color touch screen operation (Kunlun connected state).

2. Adopting four axis exchange coiling, non-stop coiling, variable frequency speed regulation, three stage counting, equipped with arc-shaped stretching rollers, which can assist in self stretching the substrate.

3. Low voltage electrical appliances: Chint or Schneider

4. All anti stick shafts are sprayed with imported Teflon

5. Transmission motor (domestic brass core)

6. Body wall panel thickness: 20-28mm

|

Mechanical roller width |

1300mm --1350mm |

|

Maximum feed diameter |

600mm-800mm |

|

Maximum winding diameter |

0-300mm (over 1000 meters) |

|

Effective width |

0-1300mm |

|

Minimum cutting width |

15mm |

|

Winding inner diameter |

3 inches |

|

Winding speed |

0-260m/min |

|

Maximum finished product winding diameter |

500mm (4-axis exchange) or maximum finished product winding diameter 1000mm(2-axis exchange) |

|

Power supply |

3-phase 5-wire 380V 50HZ or 220V 50HZ |

|

Motor power |

4HP |

|

Equipment size |

2900 * 1500 * 1600mm (slightly different) |

|

Machine weight |

1950 kg |

|

Air source |

5KG (self provided) |

Note: Our company's products are updated quickly. If there are any changes, please refer to the actual product without further notice.

15168701069

жүӢжңәпјҡ

иҒ”зі»дәәпјҡ

з”өиҜқпјҡ

дј зңҹпјҡ

ең°еқҖпјҡ

Guangzhou Baifu Machinery Manufacturing Co., Ltd. Hunan Branch

Guangzhou Baifu Machinery Manufacturing Co., Ltd. Hunan Branch

Collect

Collect Contact

Contact дёӯж–ҮзүҲ

дёӯж–ҮзүҲ

жүӢжңәеҫ®е®ҳзҪ‘

жүӢжңәеҫ®е®ҳзҪ‘